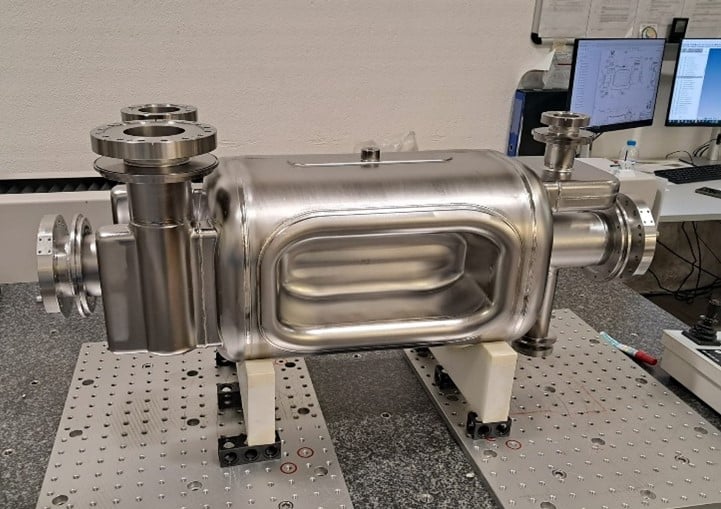

At Zanon Research & Innovation we are deeply involved in the High-Luminosity Large Hadron Collider (HL-LHC) project at CERN, in Switzerland. We are in fact contracted to manufacture, treat, and jacket a total of 12 RF-Dipole superconducting crab cavities for Fermilab, where the U.S. in-kind contribution to the HL-LHC is managed. After successful cold tests in the U.S., 10 of these cavities will make their way to TRIUMF, in Canada, for installation into 5 cryomodules, and finally shipped to CERN for installation.

The inherent complexity of the RFD cavity, combined with the stringent requirements of the HL-LHC, pose technical challenges for the manufacturing. However, two prototypes were successfully completed in the past years, and exceeded project requirements in cold tests performed in the U.S. at Fermilab and JLab.

This week, at Zanon, we have successfully completed the electron-beam welding of the first two production cavities. Activities in the next months will include processing, jacketing, final validations in the U.S., and shipment to TRIUMF. These two cavities will be the first to be ultimately installed at CERN in the HL-LHC.